CAD Micro is now part of:

Learn More >>

Together with GoEngineer, you will get local, personal customer service and support, now with access to even more resources. For more detailed questions & answers, please visit our FAQ.

CAD Micro is now part of:

3d printers

strong parts. right now.

Start printing stronger with Markforged 3D printers, software and materials. Markforged is liberating designers and engineers around the world from the long lead times and high costs of traditional manufacturing. Instead of waiting weeks and paying thousands of dollars for a part, with Markforged you can 3D print incredibly high-performance parts on-premise and in under 24 hours. Print carbon fiber for parts that are as strong as aluminum and dramatically lighter. For heat tolerance, print with 17-4 Stainless Steel. For anything else, print with Titanium, Aluminum, Kevlar, or one of their 11 other materials to fit any functional application. Welcome to the future of manufacturing.

stronger

faster

cost efficient

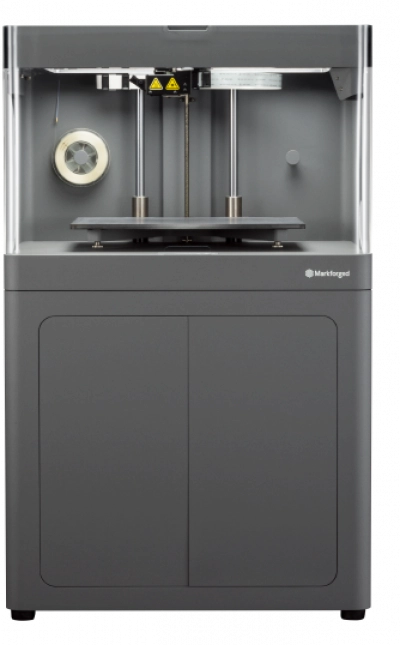

Markforged’s next generation industrial composite 3D printer

The FX10 is the newest edition to the Markforged 3D printer lineup. It is the result of years of engineering innovation, designed to deliver strong, accurate parts – every time.

Continuous carbon fiber reinforced parts, suitable for a wide range of factory floor applications

Designed to reliably deliver accurate, strong parts. Backed by Simulation and Inspection software, FX10 can produce verified parts that meet stringent factory floor requirements.

Operating on the Digital Forge: Markforged’s platform that includes software, training, and built-in cost calculation. Start generating ROI on day one and effortlessly scale.

FX10 features two print head mounted optical sensors. The laser micrometer powers Inspection — in-print dimensional validation — and machine calibration while the new Vision Module will capture detailed images of calibration parts to determine and optimize printer performance.

An inboard material chamber stores four spools in individually sealed compartments and supports auto material changeover and fast spool loading, reducing user intervention.

FX10 features a 7” touchscreen. Users can start builds, monitor machine status, manually control the machine, and start automated calibration routines all in one place.

The FX10 has a large chamber that heats to 60 °C, useful for printing high-quality parts at high speed. The aluminum vacuum bed is also heated and utilizes precision-machine grooves that are scanned by the laser micrometer for calibration.

MARKFORGED’S NEW FLAGSHIP PRINTER

A machine that brings the Digital Forge platform and Continuous Fiber Reinforcement technology to a new realm of parts, problems, and industries. Designed to tackle some of the most demanding manufacturing industries — aerospace, automotive, defense — it is ULTEM™ filament capable, bigger, faster, and more sophisticated than any of our other 3D printers.

Schedule time to learn more about how this breakthrough machine can benefit the unique needs of your business from a Markforged specialist today.

The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries

An accessible end-to-end metal 3D printing solution for funcational metal parts, next day.

Build volume: 250 mm x 220 mm x 200 mm

Layer Height: 50 μm

Technology: ADAM

The Metal X is up to 10x less expensive than alternative metal additive manufacturing technologies – and up to a 100x less than traditional fabrication technologies like machining or casting.

Markforged’s cloud-based printer management software, built-in touchscreen interface and automatic material tracking make the Metal X system the simplest way to manufacture metal parts.

with cloud eiger software

Industrial grade large-format printers deliver exceptional accuracy, reliability and repeatability. These printers are the go-to solution for manufacturing tooling (Jigs, Jaws, Tools, Fixtures). Save time and money printing tools previously machined out of aluminum.

The strength and stiffness of carbon fiber meet the versatility of tough nylon. Engineering class parts that are 20% stronger and 40% stiffer than ABS.

For load-bearing applications that require real strength, these parts make the grade. Now you can print parts faster and cheaper than machining metal.

Exceptionally strong, supremely stiff, ultra lightweight, and incredibly versatile – X7 parts deliver unparalleled performance without compromise.

The Metal X is up to 10x less expensive than alternative metal additive manufacturing technologies — and up to a 100x less than traditional fabrication technologies like machining or casting.

Our cloud-based printer management software, built-in touchscreen interface and automatic material tracking make the Metal X system the simplest way to manufacture metal parts.

Speed time from design to strong metal parts with this accessible and compact process. ADAM prints your part using a bound metal powder rod that transforms into a dense metal part in one easy step. Bulk sintering provides crystal growth through all axes giving your parts excellent mechanical properties in all directions.

with cloud eiger software

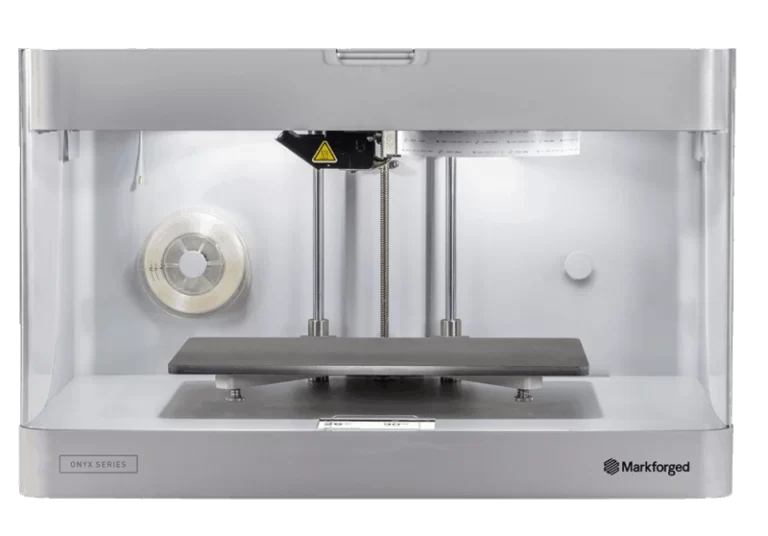

The DNA of the Industrial Series in a package that fits on your desktop. The engineering excellence of the industrial series in a form factor that fits on your desk.

For load-bearing applications that require real strength, these parts make the grade. Now you can print parts faster and cheaper than machining metal.

The Mark Two delivers industrial grade build quality and part strength in a desktop form-factor. Print incredible strong continuous carbon fiber parts.

With a one-cubic-meter build volume, it’s made to print massive, industrial parts. It’s an effective and accessible solution for the creation of demanding, geometrically complex applications in full scale that are beyond the capabilities of smaller systems.

The open frame ensures unobstructed print monitoring and easy access to the print bed. User’s can easily check the quality and progress of their print at any time and remove parts from multiple sides. Smaller moving parts are enclosed, and portal motion is protected by two pressure sensors attached to the frame at its top and bottom to ensure operator safety.

eiger 3D printing software

Dynamic additive manufacturing software that enables you to 3D print any part, on-demand at the point of need. From design to part – easier than ever before with Eiger. Designed to take you from CAD to functional part quickly, Eiger’s browser-based workflow is secure, fast, and intuitive.

RESOURCES

CAD MicroSolutions Inc. is uniquely positioned to support our clients across Canada. Visit one of our 5 locations, or contact

Our CEC provides an opportunity for customers to see, touch and interact with the technology behind Industry 4.0 – so you can try before you buy.

CAD MicroSolutions is uniquely positioned to support our clients across Canada. Our team is dedicated to helping our customers ensure they are realizing the greatest value from their technology investment.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: 1-888-401-5885

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: Toll-free: 1-888-401-5885

Complete the form below to subscribe to our newsletter.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: Toll-free: 1-888-401-5885

Complete the form below and one of our team members will reach out to you as soon as possible to confirm your booking. If you need additional support, please contact us toll-free at: Toll-free: 1-888-401-5885