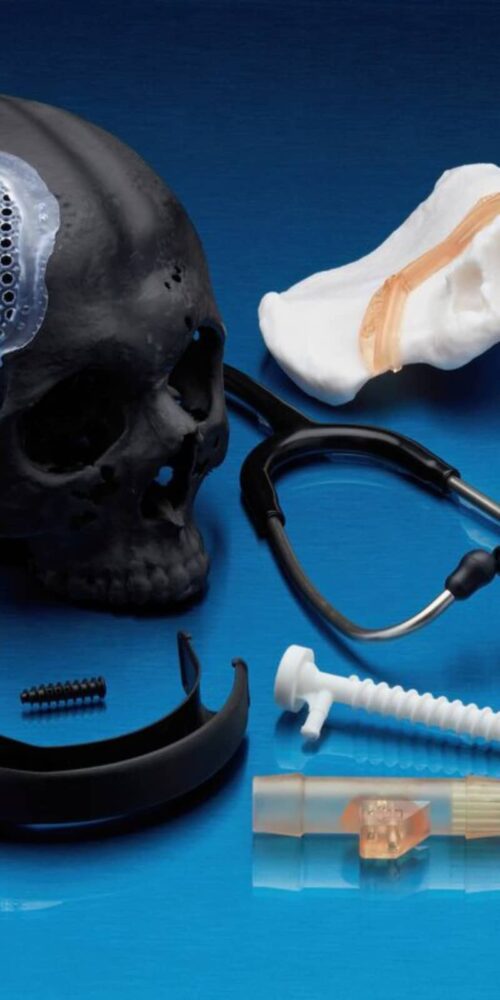

Create personalized and patient-specific medical devices, implants, orthotics and prosthetics that perfectly match their unique anatomical characteristics and needs, improving treatment outcomes and patient satisfaction.

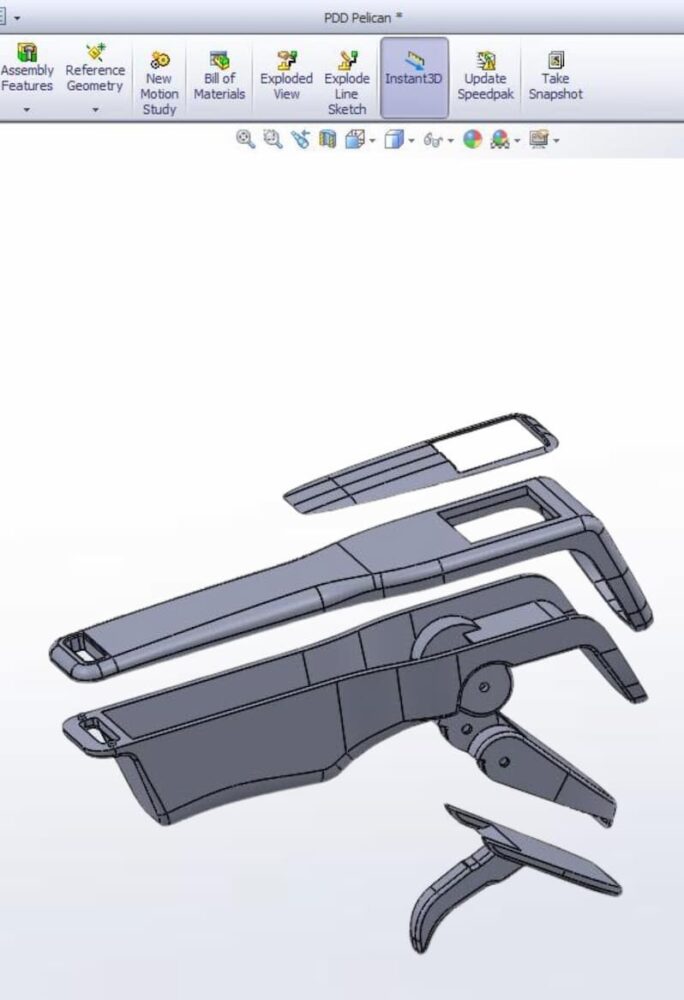

Quickly create prototypes and iterate on designs, speeding up research and development, testing and validation for new medical devices or instruments. Reduce time-to-market and speed up the innovation cycle.

Create final parts in a range of materials that have been approved for medical applications, more cost-effectively than through traditional manufacturing processes.

Produce intricate and complex geometries that are challenging or impossible to achieve with traditional manufacturing techniques. This is particularly beneficial for manufacturing medical devices, implants, and lattice structure such as may be required in patient-specific prosthetics.

Provide medical devices and components on-demand, eliminating the need for large-scale manufacturing and minimizing inventory costs. Consolidate multiple components into a single 3D printed part to reduce assembly and supply chain complexities.

Produce parts when and where they are needed, leading to more flexible, efficient, and resilient supply chains.

Producing parts with additive manufacturing leads to lower CO2 emissions throughout the product lifecyle.

Patient-specific devices, such as orthotics or prosthetics, are more comfortable and better adapted to their unique needs. 3D printing can also support the creation of patient-specific surgical guides or jigs, enhancing the precision and efficiency of surgical procedures, reducing operative time and minimizing patient discomfort.

Create anatomical models, pathology models, and medical teaching aids for visualizing complex medical concepts. Create patient-specific anatomical models from medical imaging data to aid in surgical planning, preoperative simulations, and improve surgical outcomes. 3D printed models are valuable tools for training medial students and surgeons, allowing for realistic practice and enhancing surgical skills.