With additive manufacturing, food and beverage manufacturers can quickly prototype new products and packaging designs, accelerating the product development process and reducing time-to-market.

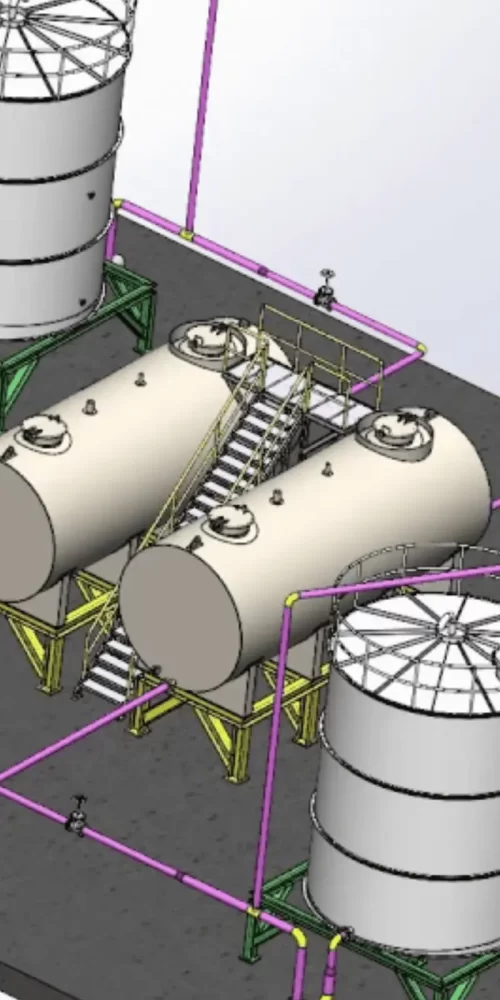

Additive manufacturing techniques enable the creation of intricate and complex food and beverage structures that are difficult to achieve with traditional manufacturing methods, offering manufacturers greater design flexibility.

Additive manufacturing enables rapid prototyping and production, reducing lead times and allowing manufacturers to respond quickly to changing consumer demands and market trends.

Additive manufacturing offers unparalleled design freedom, allowing for the creation of intricate and customized packaging designs that meet specific product requirements and branding objectives.

Unlike traditional manufacturing methods that require expensive molds or tooling for each product variation, additive manufacturing eliminates the need for tooling, resulting in significant cost savings for food and beverage manufacturers.