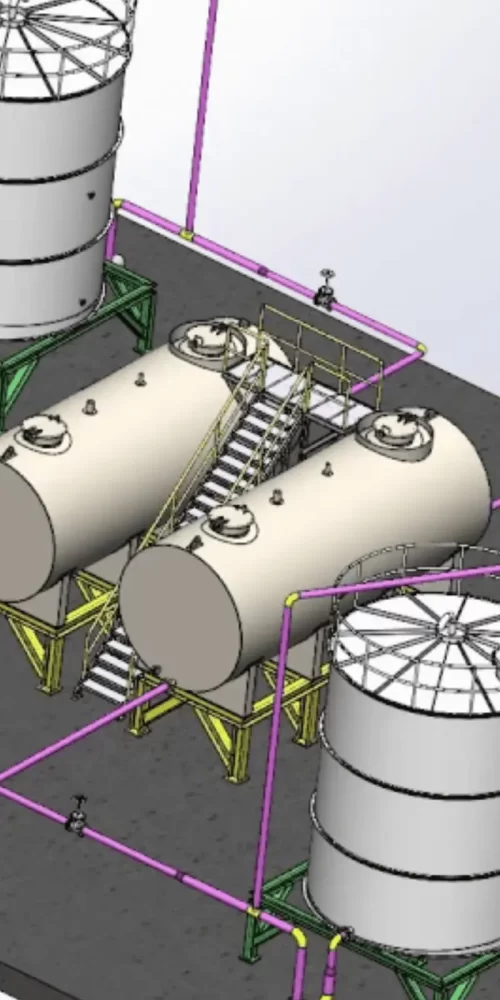

Manufacture components with complex geometries to produce parts that are more efficient, durable, and resistant to harsh operating conditions.

Print parts where you need them, when you need them to eliminate lead times, optimize supply chain management and reduce costs associated with maintaining inventory of spare parts.

Accelerate the development cycle of new equipment and systems with the ability to quickly create physical models and test, evaluate, and validate designs.

Eliminate the need for costly and time-consuming tooling processes and enable the consolidation of multiple components into a single 3D printed part, reducing assembly and inventory costs.

Enable onsite or near-site production of critical components to reduce downtime, improve operational efficiency and enhance overall field service capabilities.

Create parts with complex geometries, lightweight structures, and optimized internal channels such as impellers, valves and turbine blades with intricate cooling channels and improved aerodynamics to improve energy efficiency and reduce maintenance requirements.

High performance polymers, metals and composites can offer enhanced properties such as improved resistance to corrosion, wear, or high temperatures, resulting in more durable and reliable equipment.

Reduce material waste, optimize designs for material usage, and minimize the carbon footprint associated with traditional manufacturing processes.