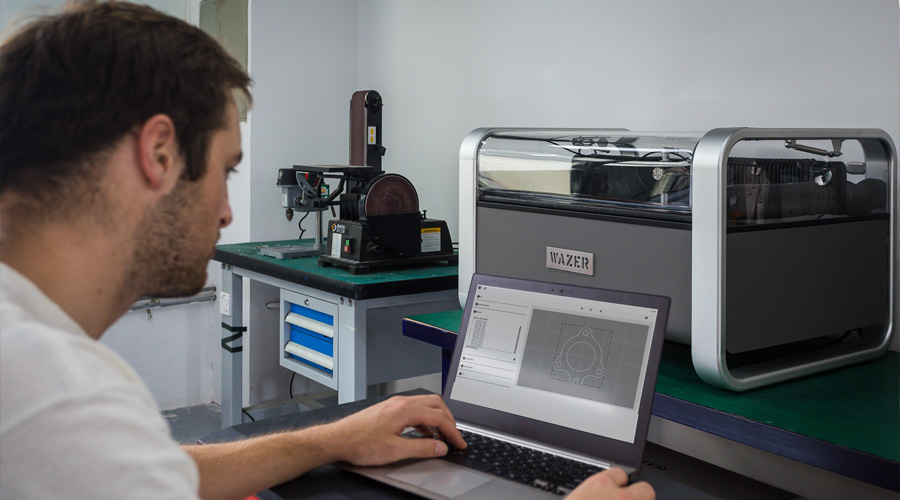

The first waterjet cutter compact in size with the ability to produce industrial grade CNC results.

Cut virtually any material. WAZER cuts everything from soft materials such as plastics & composites to tile, steel, stone, metal, glass and everything in-between – all with the precision you need for production grade finishing.