Demo: Markforged Simulation

Markforged Simulation allows you to virtually test the strength and stiffness of your parts right from your Eiger workflow – meaning you can validate your part’s performance before you hit

CAD Micro is now part of:

Markforged Simulation allows you to virtually test the strength and stiffness of your parts right from your Eiger workflow – meaning you can validate your part’s performance before you hit

Markforged Simulation vous permet de tester virtuellement la résistance et la rigidité de vos pièces directement à partir de votre flux de travail Eiger, ce qui signifie que vous pouvez

Steve Michon, President and Owner of Zero Tolerance, LLC has always been committed to investing in the highest performance technology to stay competitive and provide his customers with the best solutions. Using Eiger 3D printing software for slicing, storing and printing parts, each 3D printer is connected to a centralized, secure cloud network. In exchange for Markforged 3D printers, participating manufacturers such as Zero Tolerance will print parts for emergency aid, such as PPE, when called upon.

The aerospace industry leverages additive manufacturing (AM) for rapid response to supply chain shifts and labor availability. AM enables on-demand MRO, spare parts production, and innovation in Urban Air Mobility. This method simplifies manufacturing processes, allowing for unattended fabrication of end-use carbon fiber composites and high-performance thermoplastics, cutting lead times and costs. The e-book explores AM’s role in aerospace, compliance challenges, overlooked applications, advanced materials, and automated inspection technologies. Learn more in free e-book how AM is complimenting the aerospace industry.

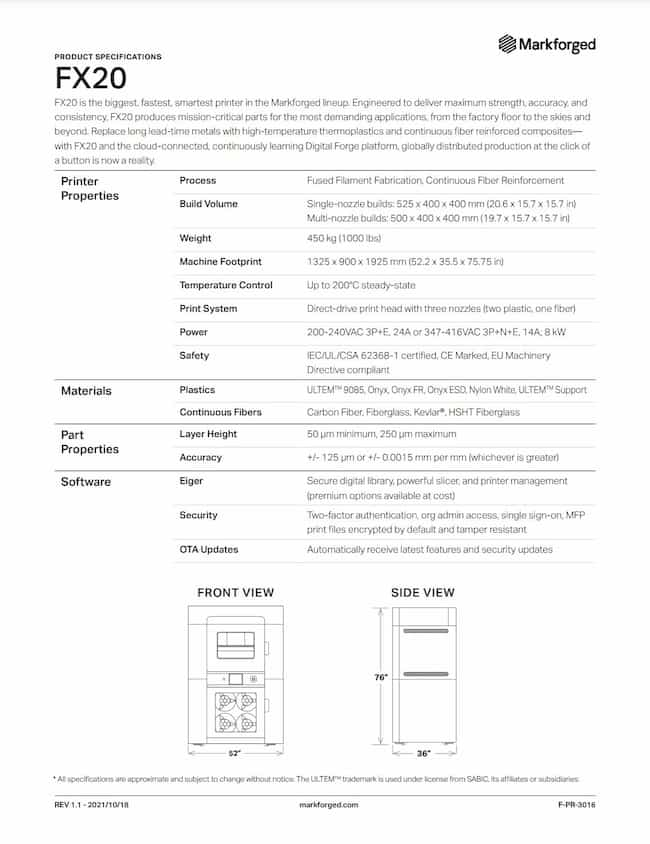

Learn more about the machine that brings the Digital Forge platform and Continuous Fiber Reinforcement technology to a new realm of parts, problems, and industries

The guide will concentrate on printers and printing technologies best suited for manufacturing applications. There are several options for printers and materials that offer the strength and chemical resistance necessary for manufacturing environments. The primary uses for 3D printed parts for manufacturing are prototyping, tooling and fixtures, and low-volume end-use parts.

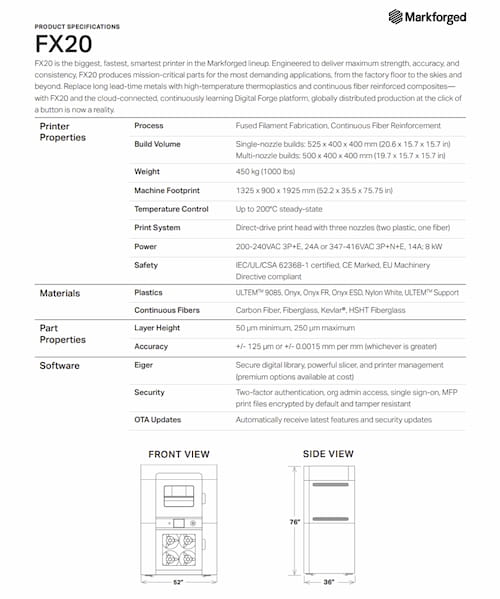

FX20 is Markforged’ss new flagship 3D printer – a machine that brings The Digital Forge platform and Continuous Fiber Reinforcement (CFR) technology to a new realm of parts, problems, and industries. Designed to tackle some of the most demanding manufacturing industries including aerospace, automotive, defense. FX20 is bigger, faster, and more sophisticated than any of Markforged’s other 3D printers. Whether your needs are tooling, prototypes, or production parts, FX20 is ready to push the bounds of additive manufacturing as we know it.

FX20 is the biggest, fastest, smartest printer in the Markforged lineup. Engineered to deliver maximum strength, accuracy, and consistency, FX20 produces mission-critical parts for the most demanding applications, from the factory floor to the skies and beyond. Replace long lead-time metals with high-temperature thermoplastics and continuous fiber reinforced composites? with FX20 and the cloud-connected, continuously learning Digital Forge platform, globally distributed production at the click of a button is now a reality

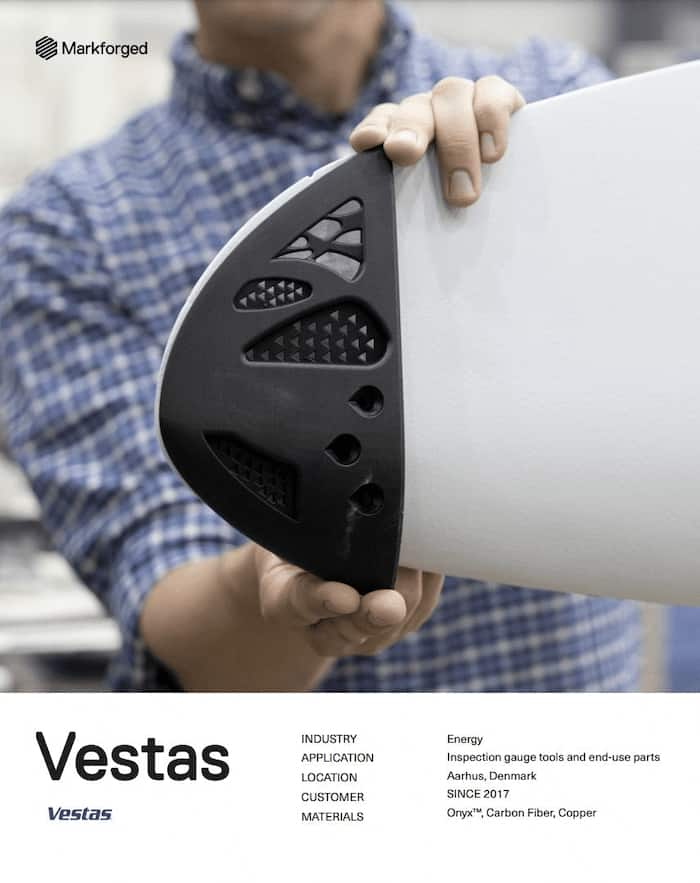

Vestas is a global leader in wind energy. With +151 Gigawatts (GW) of wind turbines in 86 countries, Vestas has installed more wind power than its competitors.

When it comes to alternative energy technology, wind turbines are easily the most recognizable. Towering at heights of 137 to 259 m (450 to 850 ft) with rotor diameter between 109-236 m (360-774 ft), they dominate their surroundings and are often visible for miles. If you?ve ever seen a wind turbine, chances are it was manufactured by Vestas.

CAD MicroSolutions is uniquely positioned to support our clients across Canada. Our team is dedicated to helping our customers ensure they are realizing the greatest value from their technology investment.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: 1-888-401-5885

Complete the form below and one of our team members will reach out to you as soon as possible to confirm your booking. If you need additional support, please contact us toll-free at: Toll-free: 1-888-401-5885