Top 5 CAMWorks Features

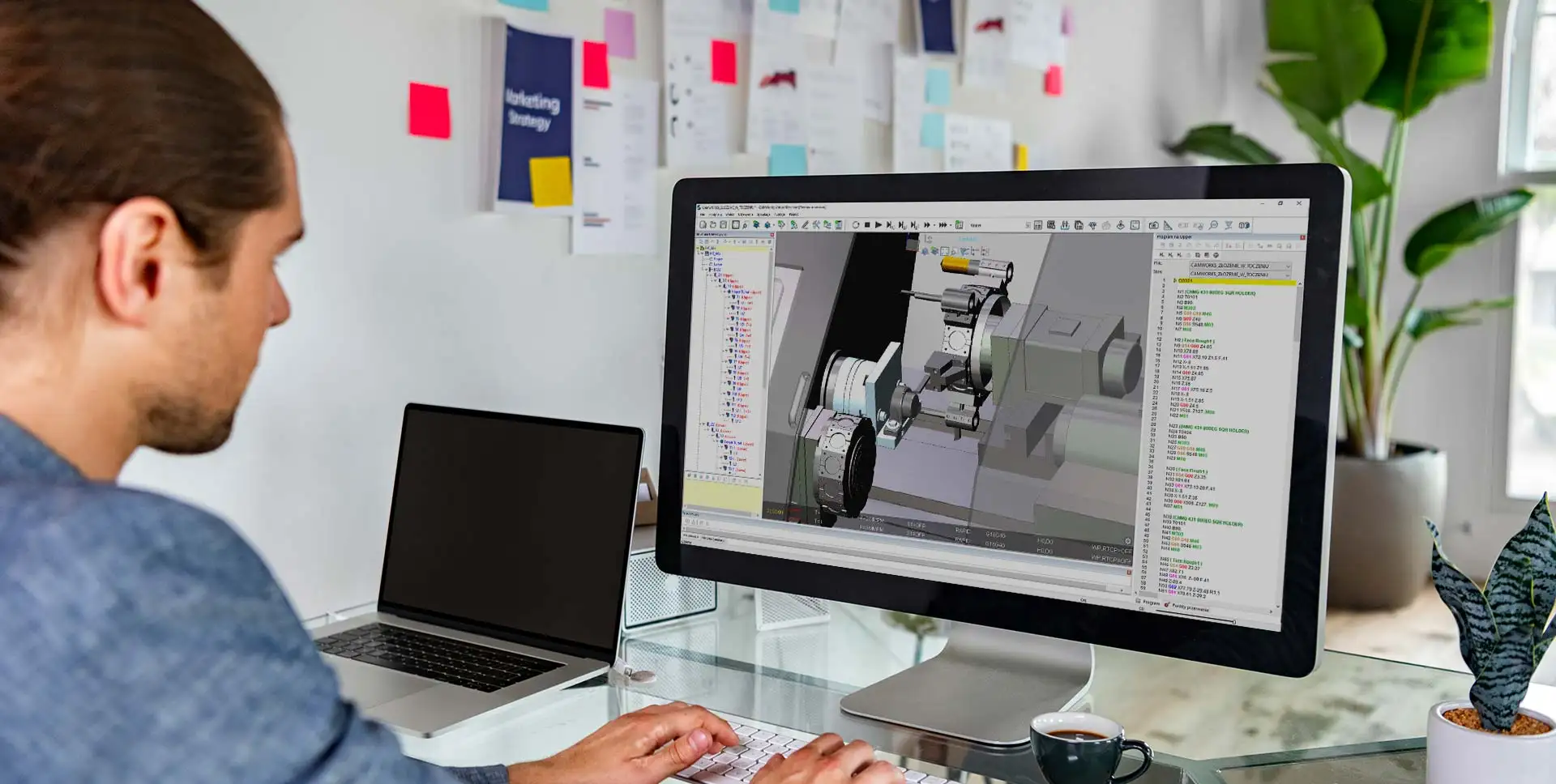

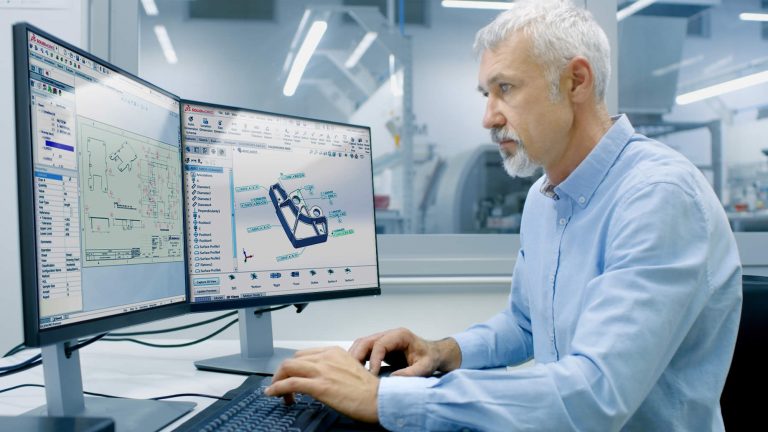

If you’re using CAMWorks for your CNC programming, you already know it offers tight integration with SOLIDWORKS and powerful automation tools. But even experienced users often miss out on some of its most productivity-boosting features – hidden gems that can save hours of time, reduce errors, and improve machining efficiency.

Here are 5 underrated CAMWorks features that could make a big impact in your workflow if you’re not using them already.