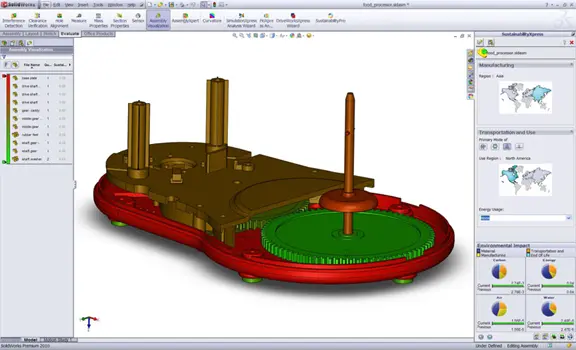

Innovative Solutions for a Greener Future in Manufacturing

Written by | Prableen Sachdeva

April 22, 2025

| 8:48 am

As we celebrate Earth Day, it’s essential to recognize the strides being made in the manufacturing industry toward more sustainable practices. Innovative solutions like SOLIDWORKS, CAM, Additive Manufacturing, and 3D scanning are at the forefront of this transformation. These technologies are not only enhancing productivity but also significantly reducing the environmental impact of manufacturing processes. Let’s explore how each of these solutions are contributing to a greener future.