Linear vs. Nonlinear Simulation: What’s the Difference?

Written by | Prableen Sachdeva

June 11, 2025

| 8:50 am

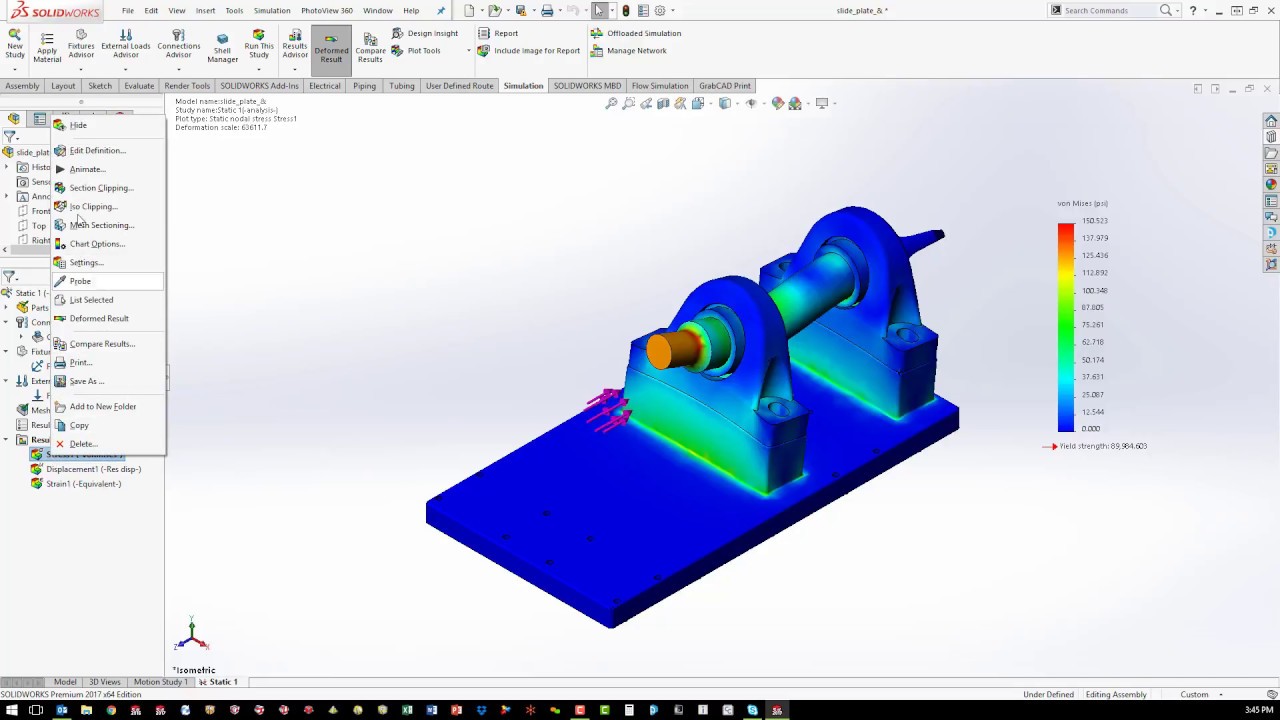

When running structural simulations in SOLIDWORKS, one of the most important decisions you’ll make is choosing linear or nonlinear analysis. While they might sound like variations of the same concept, they solve very different kinds of engineering problems.

In this blog, we’ll break down what each method does, how they differ, and when to use each one.