Product Overview: Mosaic P3

Increase throughput, expand range and automate. Discover the Mosaic Array

Automated 3D Printing

This fully automated production powerhouse contains everything Mosaic has to offer in one package – 4 Element/HT printers, 32 materials, automated print queuing and build plate removal for 10x the throughput. These features mean that your printers can be running around the clock, switching print beds and materials without human involvement and minimal downtown, making the Array the ideal solution for industries like Education, Service Bureaus or Manufacturing facilities that have a high volume of parts to produce.

The system is easy to manage with the intuitive CANVAS slicing software, and the automation features mean that you can spend less time focused on maintaining and managing your prints, and more time focused on the next project.

The increased print capacity and throughput and reduced labour requirements mean you can achieve a lower cost per part with the Array than any other industrial printing system on the market.

Large build volume and automated print monitoring means low downtime and high throughput.

Print up to 8 materials in a single part with industrial materials, including PEEK, PEKK and Ultem.

With one operator able to run the equivalent of 250 3D printers, 3D printing large production volumes is finally possible.

Construction: Durable Metal Motion Systems, aluminum outer chasis

Layer Resolution: 20-320 Microns

XYZ Resolution: 10μm, 4μm, 10μm (X ,Y, Z)

Build Volume: 4 Modules of 14″x14″x14″ (2744 cubic inches each)

Build Speed: 100 mm/s

Build Plate: Steel build plate, automatically changed via internal robotic system

Large volume prints in up to 8 different materials.

Automated systems increase throughput by up to 10 times.1

Integrated storage cart maximizes printer uptime.

Support for industrial materials including PEEK, PEKK and Ultem 9085

72+ hours of continuous unattended operation

95% more cost effective on a per print basis

Automated print bed removal, changeover, and failure detection

✓ Automated material changover and runout detection with Palette X

4 Element/ HT

3D Printers

3D Printers

4 Element/ HT

3D Printers

1 per Element Printer

32 Material

Pods

8 per Element Printer

1 Cart Stores Completed Print Beds

Stores Completed

Print Beds

Stores Completed Print Beds

1 Robotic

Arm

Stores Completed Print Beds

Reliable, Flexible & Intuitive 3D Printers

Built to withstand the manufacturing floor, the Element and Element HT are powerhouse 3D printers that offer multi-material and multicolor 3D printing with automated material handling. Combined with CANVAS slicer software, these printers automate your printing process and take care of the heavy lifting, freeing you up to focus other things.

With a hot-end temp. of up to 500°C, and a heated chamber, Element HT allows you to print high strength parts for the most demanding applications.

With an all metal gantry and a precision motion system, Element HT was developed with manufacturing level reliability in its DNA.

Element’s 14" x 14" x 14" build volume to print with up to 8 materials in a single part including rigid, flexible, and soluble support material in your prints.

Technologies: Fused Filament Fabrication (FFF), Multi-Material Extrusion (SEME)

Build Envelope: 355mm x 355mm x 355mm (14” x 14” x 14”):

Construction: Durable all-metal motion systems

Layer Resolution: 20-320 microns

XYZ Resolution: 12.5μm, 12.5μm, 0.4μm (X ,Y, Z)

Max Speed (Travel): 200mm/s

Large volume prints in up to 8 different materials

Modular printhead & hardened steel nozzle for precision printing

Support for industrial print materials like PEEK, PEKK and Ultem

Heated built plate & chamber for advanced thermal plastics1

Element HT can print high-strength parts with tight tolerences.

Controlled remotely to monitor and start prints from anywhere

Automated filament changeover to maximize printer uptime

Up to 8

Materials

Automatically switches mid-point

Industrial

Materials

Print strong functional 3d prints

Large build

volume

8 per Element Printer

Simple multi-material 3D printing.

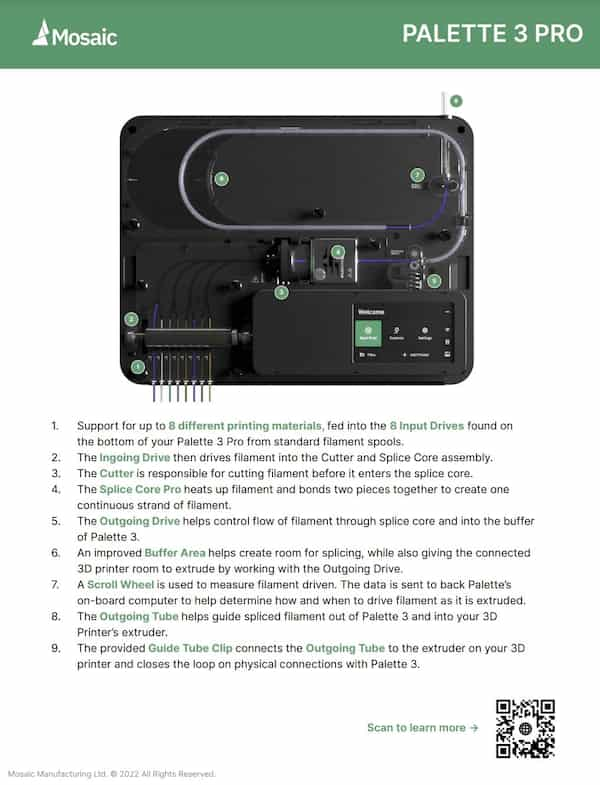

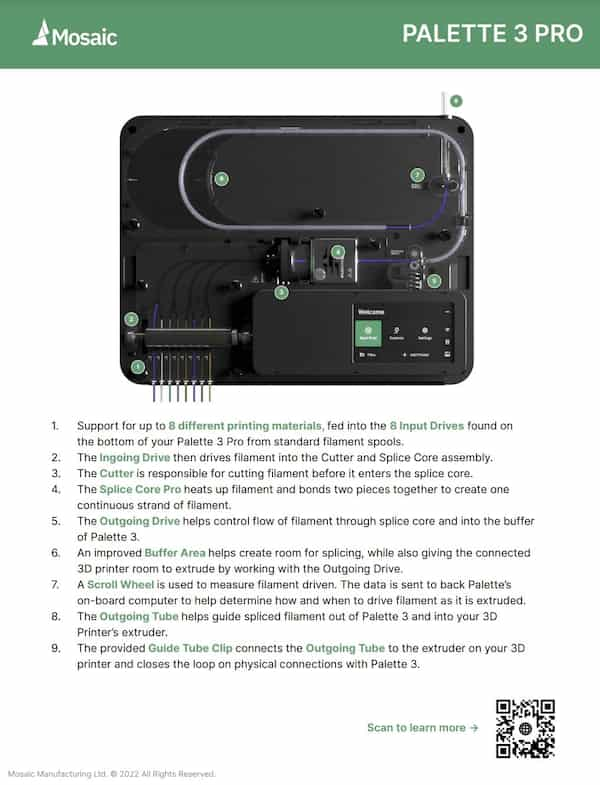

With a simple plug-and-play setup, the Palette 3 and Palette 3 Pro enable your printer to print with multiple colors in one print, so you can communicate your ideas with realistic multi-color prints in flexible or rigid materials, with breakaway or soluble supports where needed. The Palette enables you to achieve high-quality, functional prints, and will automatically splice the next spool if the previous runs out, to keep your print going. The Palette 3 works with most filament-based printers

Filament Compatibility: 1.75 ±0.03mm PLA, PETG, TPU, ABS, PVA, HIPS Shore hardness of 95A or harder

Splicing Technology: 3rd generation Splice Core PRO (P3-SCP)

XYZ Resolution: 10μm, 4μm, 10μm (X ,Y, Z)

Splicing Speed Up to 10% faster than Palette 3, 35% faster than Palette 2

Software Compatibility: Canvas

Product Dimensions (cm) 30.9 x 23.5 x 7.4 cm

Power 12V / 4A

Up to 8 different filaments in a single print job

Improved, aluminum Splice Core, 10% faster than Palette 3

Easily connects to most widely available 3D printers1

Print Modules: 4 x independent Element Array modules

Fully automated runout detection and spool changeover

Splices 10% faster than Palette 3 and rated for 2x as many lifetime splices.

Built-in Canvas Hub for improved connectivity

Up to 8

Materials

Automatically switches mid-point

Simple &

Powerful

Slice, paint, print and manage.

Easy

Setup

Power it up and connect to get started

Our CEC provides an opportunity for customers to see, touch and interact with the technology behind Industry 4.0 – so you can try before you buy.

RESOURCES

Increase throughput, expand range and automate. Discover the Mosaic Array

Help your students develop transferable skills for today’s job market,

CAD MicroSolutions is uniquely positioned to support our clients across Canada. Our team is dedicated to helping our customers ensure they are realizing the greatest value from their technology investment.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: 1-888-401-5885

Complete the form below to subscribe to our newsletter.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: Toll-free: 1-888-401-5885

Complete the form below and one of our team members will reach out to you as soon as possible to confirm your booking. If you need additional support, please contact us toll-free at: Toll-free: 1-888-401-5885