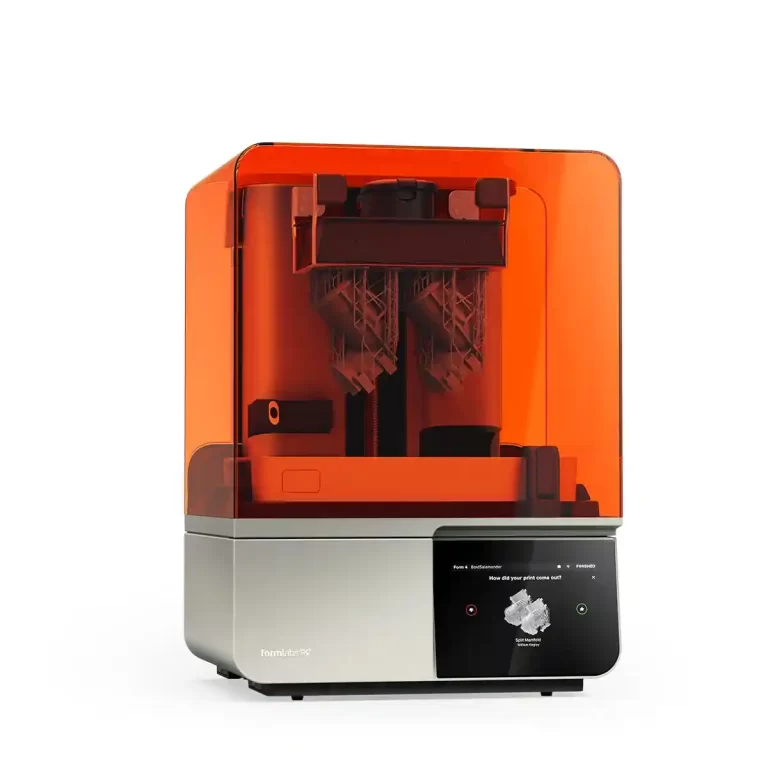

1. Speed: Up to 4x Faster

The headline feature of the Form 4 is blazing-fast print speeds, up to four times faster than the Form 3+. Thanks to an upgraded Low Force Display (LFD) 2.0 system and an all-new optical engine, Form 4 can deliver same-day iteration on parts that used to take overnight.

- Form 3+: ~25-40 mm/hr

- Form 4: Up to 100 mm/hr, depending on the material

Why It Matters: Faster print times don’t just boost productivity – they also accelerate design decisions, reduce prototyping cycles, and enable small-batch production on tight deadlines.

2. Accuracy and Surface Finish: Subtle but Solid Improvements

Form 3+ already offers excellent detail thanks to its LFS (Low Force Stereolithography) technology. However, Form 4 introduces a redesigned optical engine, enabling even more consistent exposure and sharper detail, especially for small features and fine textures.

What’s new:

- Better uniformity across the build platform

- Improved first-layer consistency

- Enhanced Z-axis accuracy in taller prints

Why It Matters: Precision and repeatability are crucial when printing functional parts, dental models, or engineering prototypes that need tight tolerances.

3. Resin Ecosystem: More Materials, Faster Cures

The Form 4 supports a growing lineup of new and reformulated resins designed specifically for its faster curing system. While many Form 3+ materials will still be supported, Form 4’s ecosystem includes next-gen resins that cure faster without sacrificing performance.

Bonus: Thanks to its closed-loop temperature control and optical improvements, even high-viscosity resins print faster and more reliably.

Why It Matters: Material choice directly affects what applications are possible, from soft-touch consumer products to high-temp tooling or biocompatible dental devices.

4. Workflow and Usability Enhancements

Form 4 refines the entire user experience – from touchscreen responsiveness to resin cartridge handling.

Key upgrades:

- Larger, more responsive touchscreen interface

- Faster boot-up and slicing times

- Smoother resin loading and tank installation

- Improved print failure detection and part removal process

Why It Matters: These quality-of-life updates reduce friction in daily use, especially valuable in a team or production setting where uptime is critical.

5. Backward Compatibility and Transition Considerations

If you’re already using a Form 3+, the good news is that many of your accessories (like the Form Wash and Form Cure) will still work with Form 4.

However, some materials and build platforms are Form 4-specific, so you’ll want to review compatibility carefully if you’re managing multiple machines.

Why It Matters: Form 4 is designed to scale with your needs. Whether you’re upgrading a single printer or expanding your print farm.