Contact

CAD MicroSolutions Inc. is uniquely positioned to support our clients across Canada. Visit one of our 5 locations, or contact

CAD Micro is now part of:

3D Printers

BigRep 3D printers are affordable and easy-to-use technology designed for large objects and ideas. Created for a range of industrial applications from rapid prototyping to finished products. Advance your manufacturing capabilities with BigRep printer’s size, speed, and agility – so you can get your products to market ahead of the competition.

Parts up to 1m³

Ford's strategy for

industrial efficiency

Proven by customers

like Kawasaki

world leading productivity at an accessible price

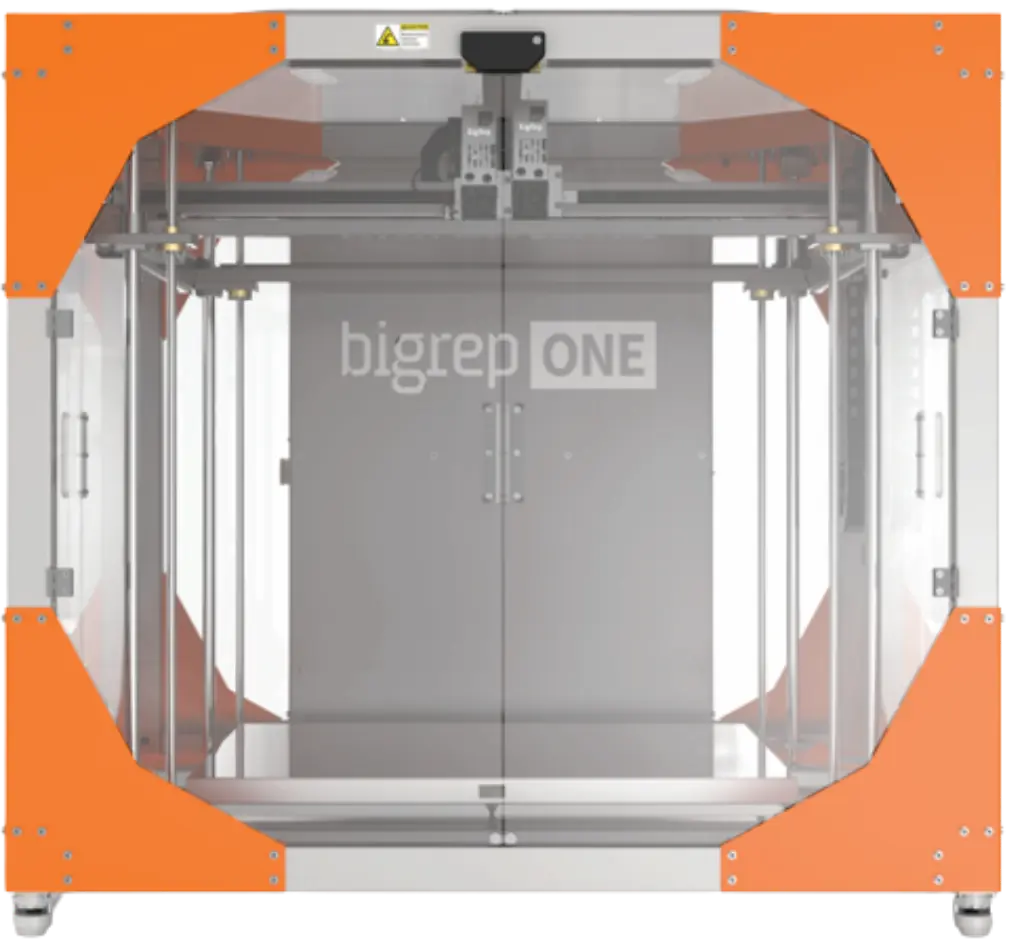

Featuring a massive one-cubic-meter build volume, the BigRep ONE works quickly and reliably to bring your designs to life in full scale. Perfect for high-strength industrial applications or prototyping in full scale, the ONE comes equipped with two BigRep Power Extruders that feature interchangeable 0.6, 1.0 and 2.0 (mm) nozzles for high-flow or maximum detail additive manufacturing.

The BigRep ONE maintains the impressive on-cubic meter build volume of its predecessor, designed for producing large 3D prints over 1000x1000x1000 mm in size. It is perfect for demanding and geometrically complex applications, allowing you to print parts in full scale, surpassing the limitations of smaller systems.

The robust, open industrial design ensures unobstructed print monitoring and easy access to the print bed from three sides. This allows you to check print quality and progress at any time. The optional enclosure add-on maintains a stable printing temperature and ensures CE-compliant operator safety.

The BigRep ONE’s print bed now features magnetic SWITCHPLATE options for maximum material range, offering strong adhesion for different materials. It retains its original integrated inductive sensor for semi-automatic bed leveling, simplifying platform calibration.

The Keep Dry Box Add-On protects filament from moisture and dust, ensuring optimal storage conditions. It fits all standard spool sizes, including two spools of up to 8 kgs. An out-of-filament sensor pauses printing so you can replace the empty spool, which is particularly useful for very large prints.

The intuitive user interface on the machine’s touch panel simplifies access to convenient features. You can remotely load, check print progress via webcam, change print parameters, and resume printing after a power failure, all from the touch panel.

Iterate Fast. Produce Faster. Get to Market Fastest

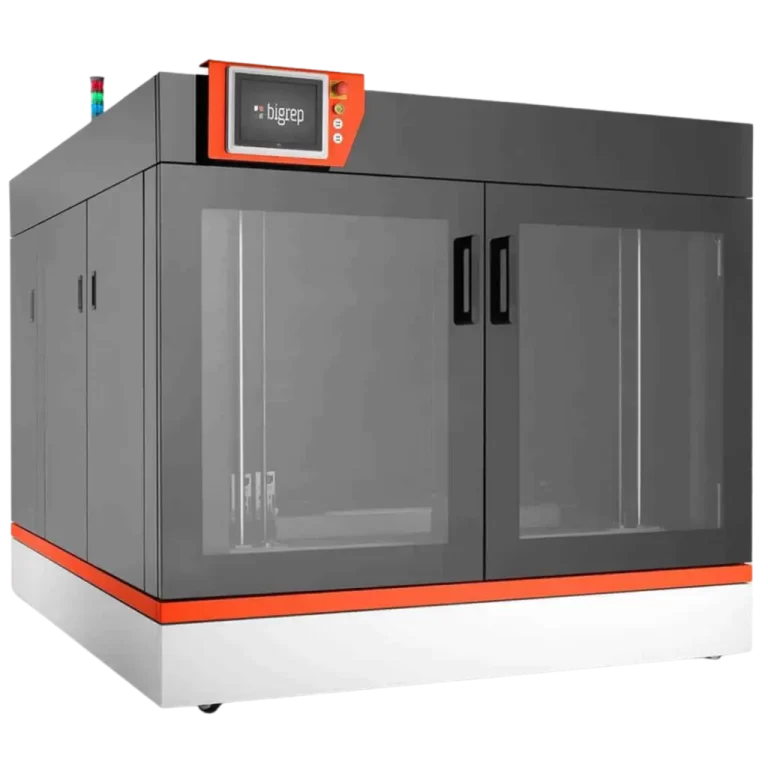

German-engineered for speed and precision, the BigRep PRO is a large-scale machine for industrial solutions. Whether for functional prototypes, composite tooling or end-use parts, the BigRep PRO is a solution that delivers. Equipped with a state-of-the-art Bosch CNC system, new Metering Extruder Technology (MXT), an enclosed build chamber and temperature-controlled filament chambers, the BigRep PRO is a 3D printer that responds to market demands.

Designed to print massive, industrial parts, as well as batches of smaller parts, its fully enclosed one cubic meter build volume ensures consistent print temperatures and safety from hazards on the factory floor.

The proprietary Metering Extruder Technology (MXT®) achieves high speed and precision in thermoplastic extrusion. This one-of-a-kind extruder enables ultimate control of engineering-grade material deposition, ensuring the high-quality parts that meet the demands of industrial professionals at speeds up to 230 g/h, 3x faster than traditional extrusion technology.

BigRep’s Advanced Capability Extruder (ACE) expands the material capabilities of the PRO while still reliably delivering quality prints with speed and precision. ACE is a direct drive extruder, perfectly equipped for fiber reinforced materials such as BigRep’s HI-TEMP CF. With ACE you can print large-format, strong parts 50% faster than other large-scale printers.

An advanced Bosch Rexroth CNC motion-control system elevates the PRO’s responsiveness for unquestionable speed, precision, and repeatability. Local data collection for real-time monitoring with 32 integrated sensors ensures optimal print process and reliability. Fleet management is made easier with live webcam view of print progress.

The PRO’s massive 1m3 build volume is supported by its custom-built, heavy duty gantry engineered for high speed, fast acceleration, and heavy payloads. Its robust welded frame eliminates vibrations during printing assuring smooth movement of the extruders that glide along a reinforced double rail system. Sturdy Bosch servo motors power the precise movement with internal encoders able to calculate real-time location of the print head and self-monitor for position accuracy.

The PRO’s environmentally sealed filament chamber ensures that stocks of all materials, including engineering-grade and water-soluble, can be well maintained and remain consistently dry in ideal operating condition for reliable, repeatable, and quality printing.

World leading productivity at an accessible price

Made for abrasive and engineering-grade materials in a size suitable for any work environment. BigRep’s STUDIO G2 is a durable, and cost-effective 3D printer for innovation and industrial production. The rapid-heating print bed and temperature-controlled filament chamber enable the printer to produce incredible, high-quality parts in engineering-grade materials. It’s sleek, space-conscious size makes it suitable for all workspaces, from design labs to production floors.

The STUDIO G2’s incredible 1000 x 500 x 500 (mm) build volume creates room for innovation by unlocking full-scale additive manufacturing.

Made for printing with advanced, engineering-grade filaments at high speed, the specially designed extruder achieves reliable, high flow rates to quickly produce industrial tooling up to a meter long with the options you need to perfect a part’s mechanical properties.

The fully enclosed, temperature-controlled build envelope is the perfect environment to achieve consistent, high-quality print results. It provides users with safe and easy access to the print bed and the ability to visually monitor the printing process in a contained space.

With the BOFA air filtration system, you’re taking every step to ensure health and safety and compliance with present and future regulations while working with any potentially hazardous materials.

Preparation time is significantly reduced for all print projects with the G2’s fast-heating print bed, capable of reaching 80 °C for optimal print bed adhesion with a variety of high-quality materials in just 15 minutes.

Two heated filament chambers ensure that engineering-grade materials with sensitive environmental requirements remain dry in a consistently controlled environment for best-in-class quality.

Iterate Fast. Produce Faster. Get to Market Fastest

With an expansive build volume, it delivers unrivaled reliability with up to 4 state-of-the-art extruders. These controlled dual extruders with their respective backups are groundbreaking in additive manufacturing, delivering flawless prints every time. The high-temperature capabilities enable peak-level 3D printing for demanding applications from aerospace to defense to automotive industries.

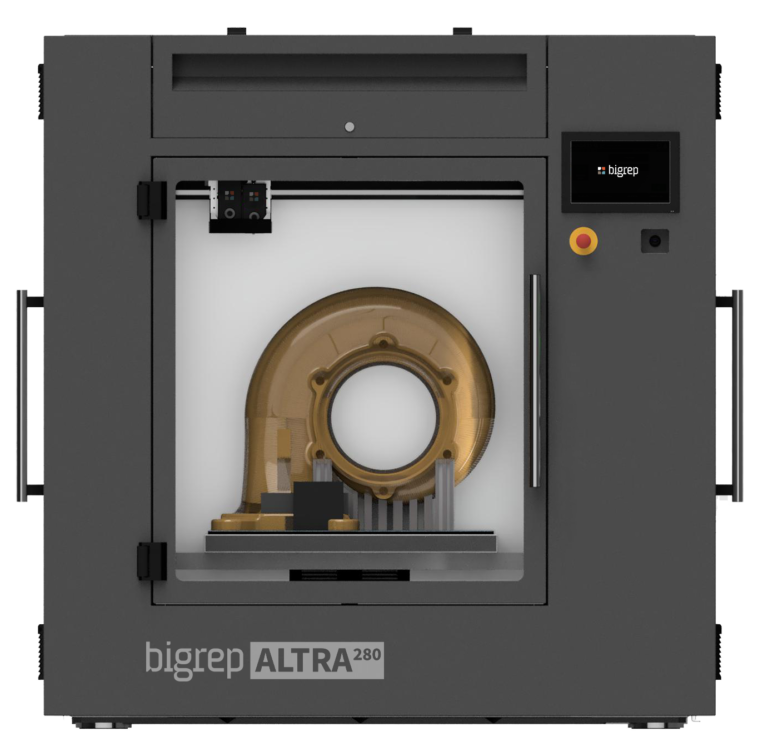

The ALTRA 280 is everything at once – a large, fast, reliable, high-temp industrial machine. It delivers complex production-quality parts without compromise.

The ALTRA 280’s 500 mm x 700 mm x 800 mm build chamber ensures accurate, large-scale prints with advanced CNC technology components.

Capable of reaching 180°C, the ALTRA 280 supports advanced materials like ULTEM 9085 and PEEK for enhanced part stability.

The ALTRA 280 features up to 4 Direct Synchronized Extruders, capable of printing at 450°C and handling up to 20kg per cycle, with dual extruders for complex prints and two backup extruders for seamless production

Automated functions, including print bed calibration and numerous sensors, enable easy startup and continuous 24/7 operation.

The heated vacuum print bed, reaching up to 180°C, ensures secure adhesion and easy removal of prints with consistent temperature control.

Uniform heat distribution and precise tempering provide high mechanical performance, preventing delamination and inconsistencies.

World leading productivity at an accessible price

An industry all-rounder high-temp machine at an unbeatable price–to–performance ratio, most automated, reliable, and fastest way to get robust, high-performance parts in the hands of industrial engineers and designers.

Aptly called the tool maker’s tool, it is a blazing hot machine of 105 liters reaching 100°C with a print bed heating up to 180°C. It is built with state-of-the-art dual extruders capable of printing high-performance materials with open access to the world’s most advanced materials, including PC, PEKK, and PEKK-CF.

With a build chamber of 400 mm x 600 mm x 440 m (build volume of 105 liters) IPSO hits a sweet spot between a desktop and a large-scale 3D printer, perfect for many tooling applications. Thanks to its made-to-last industrial components and stepper motors with encoders, IPSO 105 achieves the level of accuracy and repeatability you expect in an industrial machine.

The IPSO 105 3D printer offers advanced high-temperature capabilities with a 100°C build chamber, 180°C print bed, and 450°C extruder. This allows for versatile material use, suitable for engineering-grade parts and functional prototypes. Its precision and temperature range ensure reliable performance for diverse applications.

The 2 DSX (Direct Synchronized Extruders) are capable of printing at 450°C and have integrated cooling channels and multiple sensors for monitoring and control. When filament runs out the Relay Mode kicks in and the second extruder seamlessly takes over. The DSX extruders are particularly good with soft, flexible materials (up to 70A) thanks to its short filament path and optimized feeding mechanism.

Getting started is quick and easy thanks to the numerous automatic functions like bed calibration via topology measurement and corresponding automatic compensation. After a smooth start, many built-in sensors will secure your 24/7 operation while the HD wide-angle camera enables real-time remote monitoring so you won’t miss a thing.

Improve your print success thanks to the evenly-heated print bed offering two print surfaces. One option, a specialized tempered glass plate, displays minimal thermal expansion delivering more accurate prints with a wide range of materials. The other is a flexible steel plate with a magnetic foil and PEI coating for easy print removal.

Consistent temperature is key for excellent prints and a requirement for high-performance parts. Reaching temperatures up to 180°C, the IPSO 105’s print bed maintains uniform heat distribution. The well-insulated build chamber circulates air heated up to 100°C assures optimum mechanical performance and print quality.

Iterate Fast. Produce Faster. Get to Market Fastest

A state-of-the-art 3D printer designed for continuous industrial manufacturing. It features advanced automation, including Relay Mode for extruder backup, automatic print bed calibration, auto-sequential printing, and the Infinity Box for automated filament handling. With dual Smart Manufacturing Extruders and an intuitive interface with animated guides, the VIIO 250 simplifies the industrial 3D printing process.

Engineered for high efficiency, it reduces energy consumption while producing high-quality functional parts affordably. This boosts productivity and cuts costs, allowing to print more parts in less time.

Achieve maximum geometric accuracy with the VIIO 250’s actively temperature-controlled build chamber (1000 x 500 x 500 mm, 250 liters) heating up to 50°C. Its compact, robust design offers large-format printing and fits any workspace. Automatic portal leveling ensures consistent print quality even after relocation.

Enjoy the comfort of a desktop 3D printer at an industrial level with the VIIO 250’s automated bed mapping, filament flow rate adjustment, and x/y calibration. The Infinity Box and Relay Mode enable uninterrupted, unattended production by automatically loading new filament and providing auto-backup extruder functionality. Additionally, its new controls platform offers industrial CNC quality and instant over-the-air software updates.

The VIIO 250 features dual Smart Manufacturing Extruders (SMX) that print up to 350°C with engineering-grade and carbon-fiber materials, equipped with LED indicators for status updates. Intelligent embedded sensors and three nozzle sizes (0.4mm, 0.6mm, 1.0mm) ensure quick, high-resolution complex 3D prints

The new multi-lingual user interface features animated guides for easy, intuitive 3D printer operation with clear information, statuses, alerts, and warnings. The Print Queue feature allows efficient workflow management by letting you check and assign the order of your prints for maximum productivity.

Press print and walk away without worrying about filament running out thanks to the Infinity Box add-on. This automatic filament handler detects when material runs out during a print job and loads new filament without intervention. It also serves as an active keep-dry box, storing filament in optimal conditions and holding up to four 8kg spools.

The print bed heats up to 120°C, ensuring uniform heat distribution and strong part adhesion with the flexible, removable SWITCHPLATE® surface. This magnetic SWITCHPLATE holds prints securely during printing and allows easy removal when cooled. It also comes in different coatings for various materials, expanding your material options.

Our CEC provides an opportunity for customers to see, touch and interact with the technology behind Industry 4.0 – so you can try before you buy.

RESOURCES

CAD MicroSolutions Inc. is uniquely positioned to support our clients across Canada. Visit one of our 5 locations, or contact

Explore our comprehensive catalog of industrial 3D printers, we offer cutting-edge technology for precise manufacturing. Stay ahead of the competition.

CAD MicroSolutions is uniquely positioned to support our clients across Canada. Our team is dedicated to helping our customers ensure they are realizing the greatest value from their technology investment.

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: 1-888-401-5885

Complete the form below, and a member of our expert team will reach out to you as soon as possible. If you require immediate assistance please contact us toll-free at: Toll-free: 1-888-401-5885

The dependable solution to dry, store, and anneal your 3D prints for optimal performance

Complete the form below and one of our team members will reach out to you as soon as possible to confirm your booking. If you need additional support, please contact us toll-free at: Toll-free: 1-888-401-5885